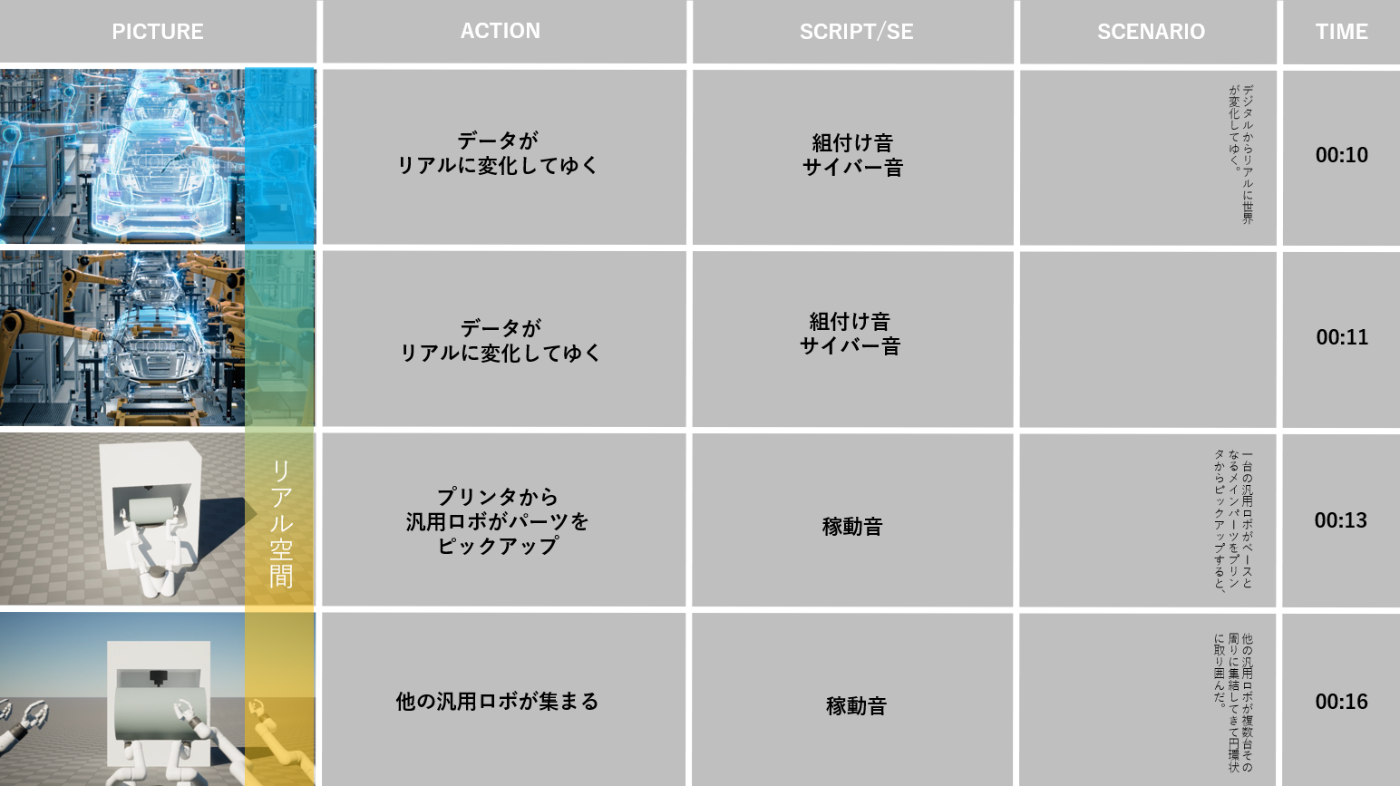

Tomorrowʼs Manufacturing Vision Video2024.06.28

We designed a vision of DENSOʼs future manufacturing and created a video to convey it.

-

Yuki

Yuki

Yoshioka -

Yuji

Yuji

Tsuchiya -

Akira

Akira

Okamoto -

Kohji

Kohji

Ohyama -

Kohei

Kohei

Akiyama

Imagining and Creating the Future

For 70 years, DENSO has been advancing automation with robots and enhancing production efficiency through human-robot collaboration. Considering the future decrease in the workforce and the need for improved workplace safety, what should future work and manufacturing look like? Designers and engineers engaged in extensive discussions to shape this future vision.

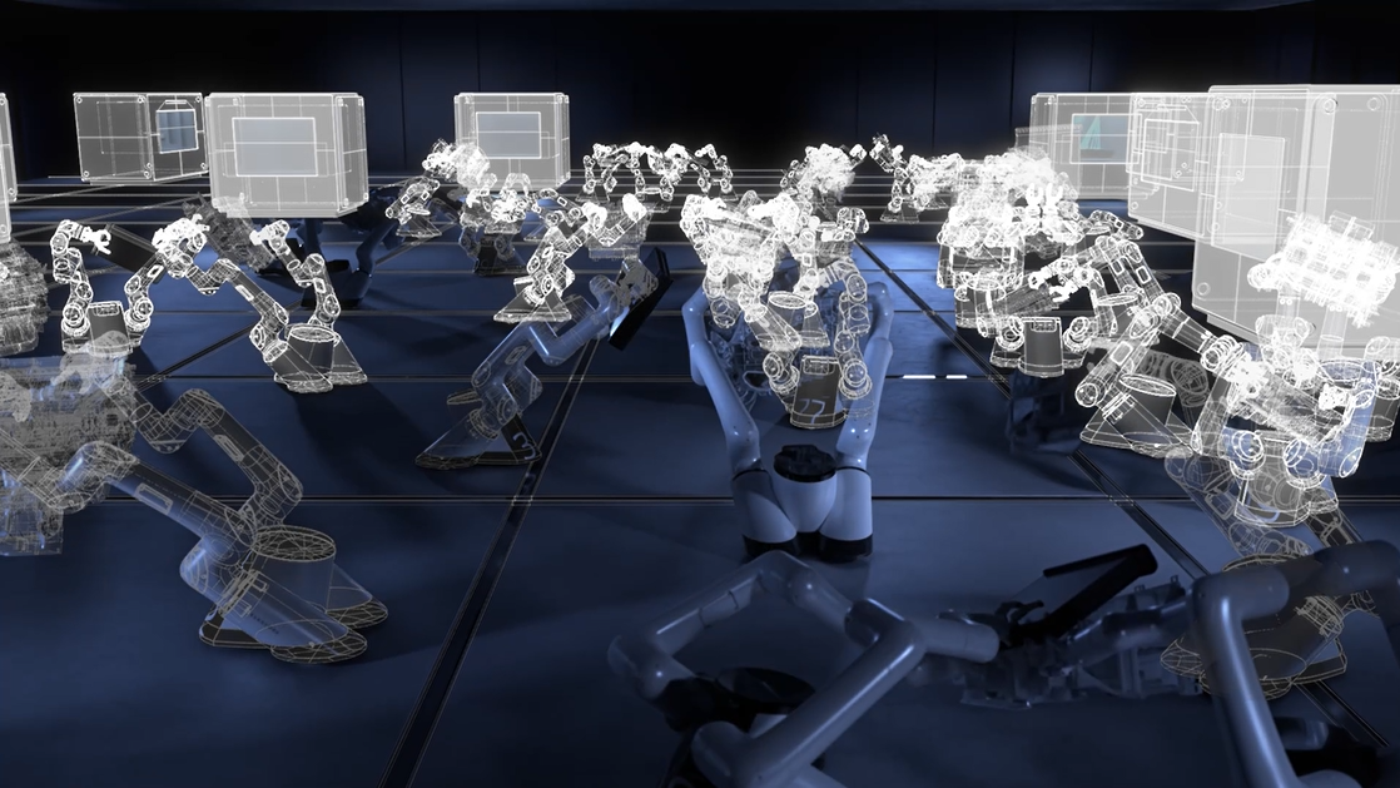

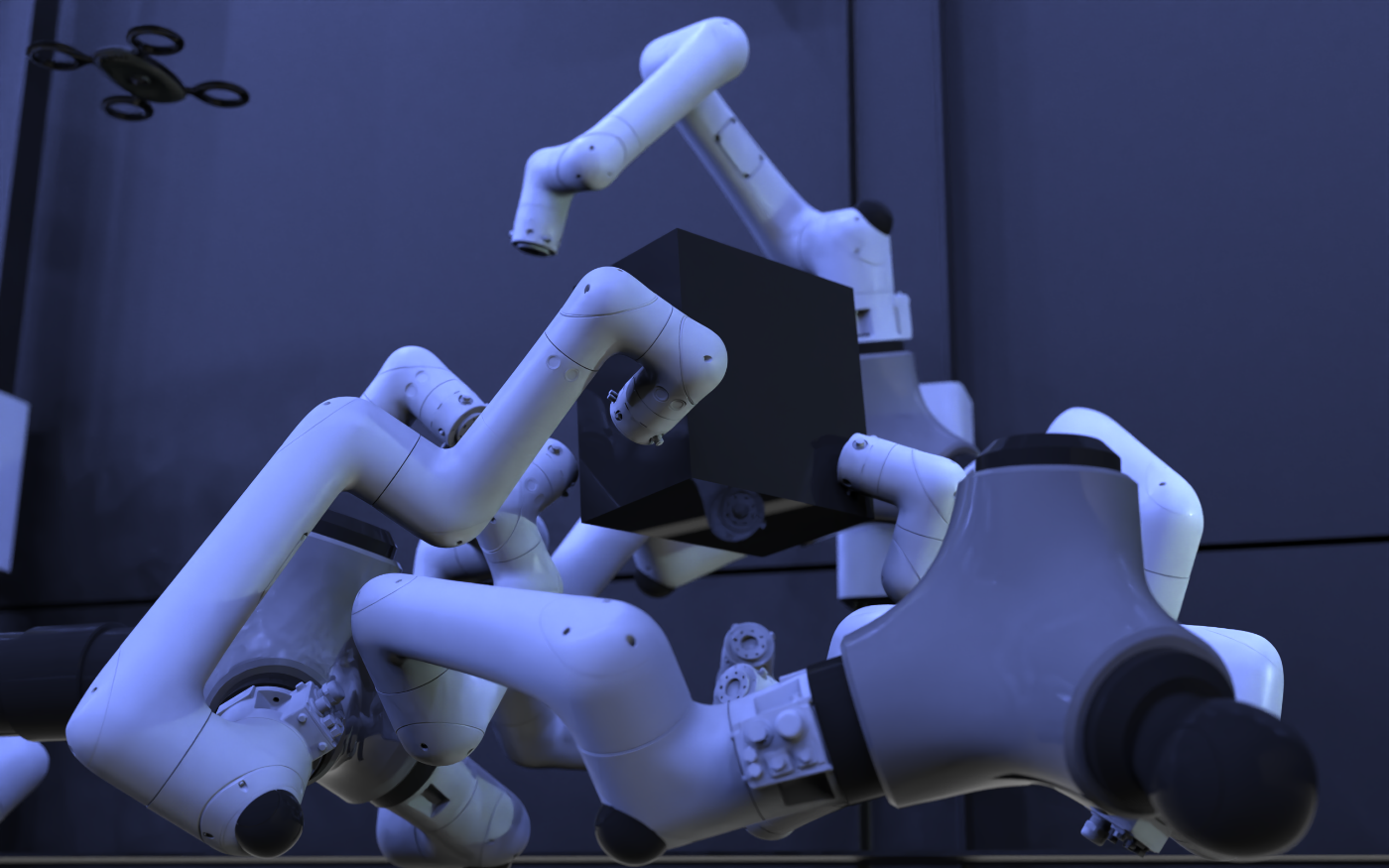

The envisioned production site is fully automated with robots autonomously carrying out manufacturing tasks. Since human presence is not assumed, there is no need for lighting, air conditioning, safety equipment, or space, leading to a high-density, highly efficient, safe, and environmentally friendly production environment. We imagined robots evolving optimally for general tasks in this setting, with the concept of dual-arm autonomous robots working in teams. All production information is digitized and reconstructed in a digital twin environment, becoming the workplace for humans. This allows access to the virtual factory and digital information from anywhere, enabling more creative work using data.

The envisioned production site is fully automated with robots autonomously carrying out manufacturing tasks. Since human presence is not assumed, there is no need for lighting, air conditioning, safety equipment, or space, leading to a high-density, highly efficient, safe, and environmentally friendly production environment. We imagined robots evolving optimally for general tasks in this setting, with the concept of dual-arm autonomous robots working in teams. All production information is digitized and reconstructed in a digital twin environment, becoming the workplace for humans. This allows access to the virtual factory and digital information from anywhere, enabling more creative work using data.

Attention to Sound

The first half of the video showcases people working creatively in a bright tone, while the second half uses a darker tone to represent the environment and technology, illustrating two contrasting worlds.

Realistically Portraying a Non-Existent World

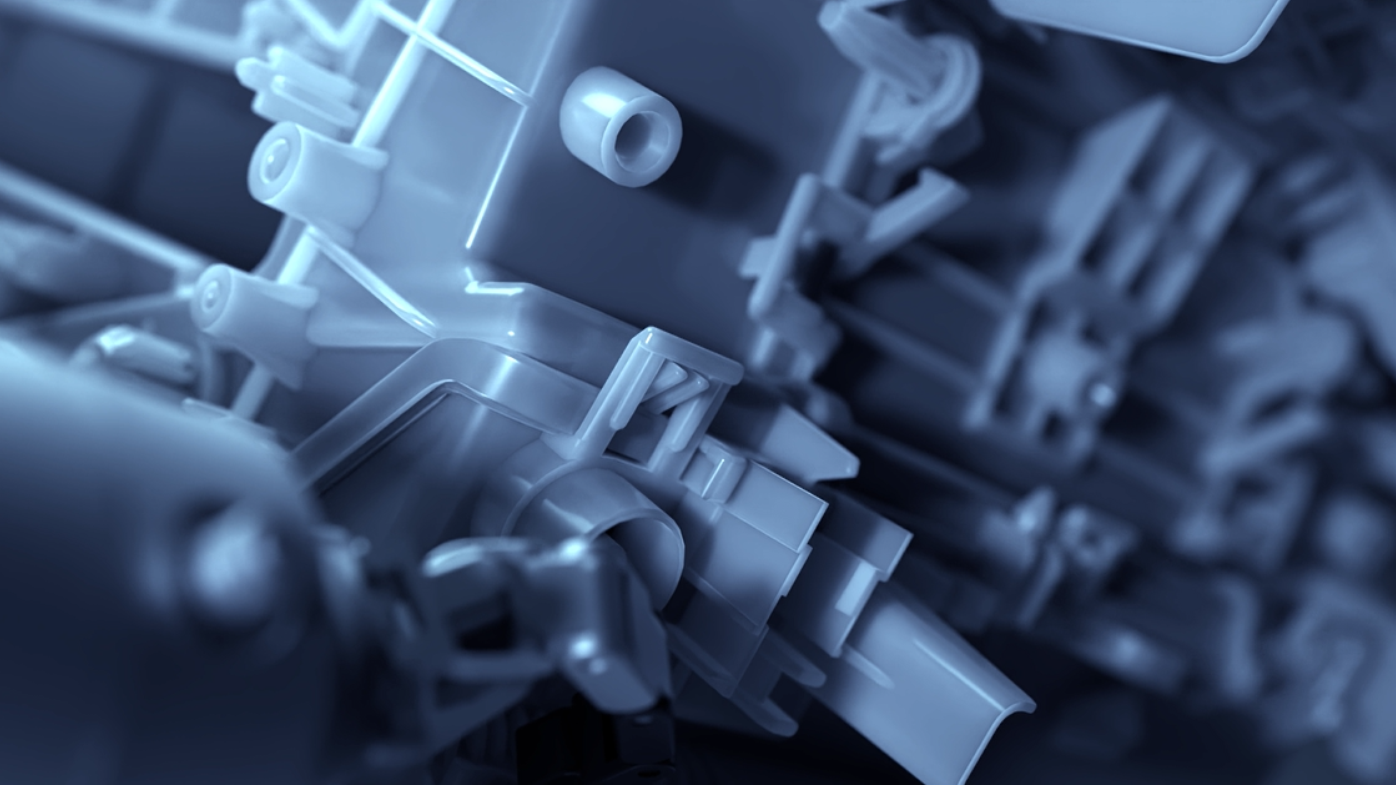

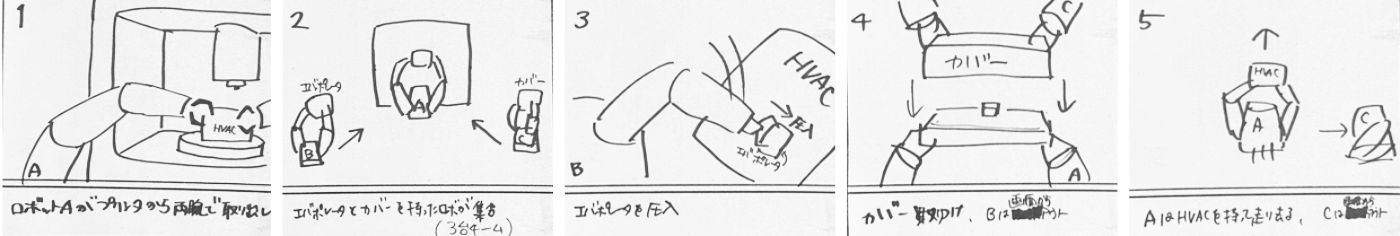

For the video, we started by visualizing the world and concept and creating a scenario to convey it. Expressing the vision in words allowed us to concretize the video image and share and discuss it within the team. We then created storyboards and detailed lighting and other elements. To add realism to the parts assembly scenes, we brought in actual parts designers and repeatedly simulated assembly actions to plan the robotʼs movements.

While the robot arms were based on the existing "COBOTTA PRO" to ensure realism, the vehicle body to which the arms attach and the positioning and angle of the arms were not predefined. We created models with a 3D printer to confirm the arm movements and finalize the design. We believe that examining as much as possible in a realistic manner adds authenticity to the video.

Tags

Member

Project Management: Yuji Tsuchiya

Project Lead: Yuki Yoshioka

Art Direction: Yuki Yoshioka

Product Design: Akira Okamoto, Kohji Ohyama, Kohei Akiyama

-

Yuki

Yuki

Yoshioka -

Yuji

Yuji

Tsuchiya -

Akira

Akira

Okamoto -

Kohji

Kohji

Ohyama -

Kohei

Kohei

Akiyama

Other WorksAll Works

ActivitiesAll Activities