Stopped Air Conditioner

Everycool2023.10.16

Everycool is an electric cooler that can be used in trucks when the engine is turned off. It provides cold air instantly, whether in the driverʼs seat or the rear bed space.

The Stopped Air Conditioner Project

Kasai: This project was initially called the "Stopped Air Conditioner." Itʼs like an aftermarket cooler installed behind the passenger seat of a truck. The product was designed so truck drivers could rest or wait during cargo loading/unloading with the engine off, still enjoying cool air. The original request from the technical department was mainly about the styling of the product. However, they also expected added value from the design, such as making the product more convenient and user-friendly, finding a place for the remote control, and making the unit appear smaller in the tight cabin space.

The project started about a year ago (around summer 2022). I initially worked on it alone, but when I was transferred, I passed the baton to Mr. Oyama and Mr. Yoshida.

Oyama: By the time I took over, Kasai had nearly finalized the main unit design for air output. My task was to handle the graphics for the controller and consider strategies for expanding sales.

Designing for Smaller Size and Smaller Appearance

Kasai: Since the product would be installed in a narrow truck cabin, compactness was essential. However, by the time the design department received the request, the internal structure and component layout were mostly finalized due to mechanical constraints. We couldnʼt make significant structural changes, so we focused on two axes: "actually making it smaller" and "making it appear smaller."

To actually make it smaller, we discussed with the engineers how we could move certain parts or change screw positions. The product would be installed in a sleeping space behind the truck driverʼs seat, so we considered how to minimize obstruction, like designing the unit to reduce interference with the driverʼs feet.

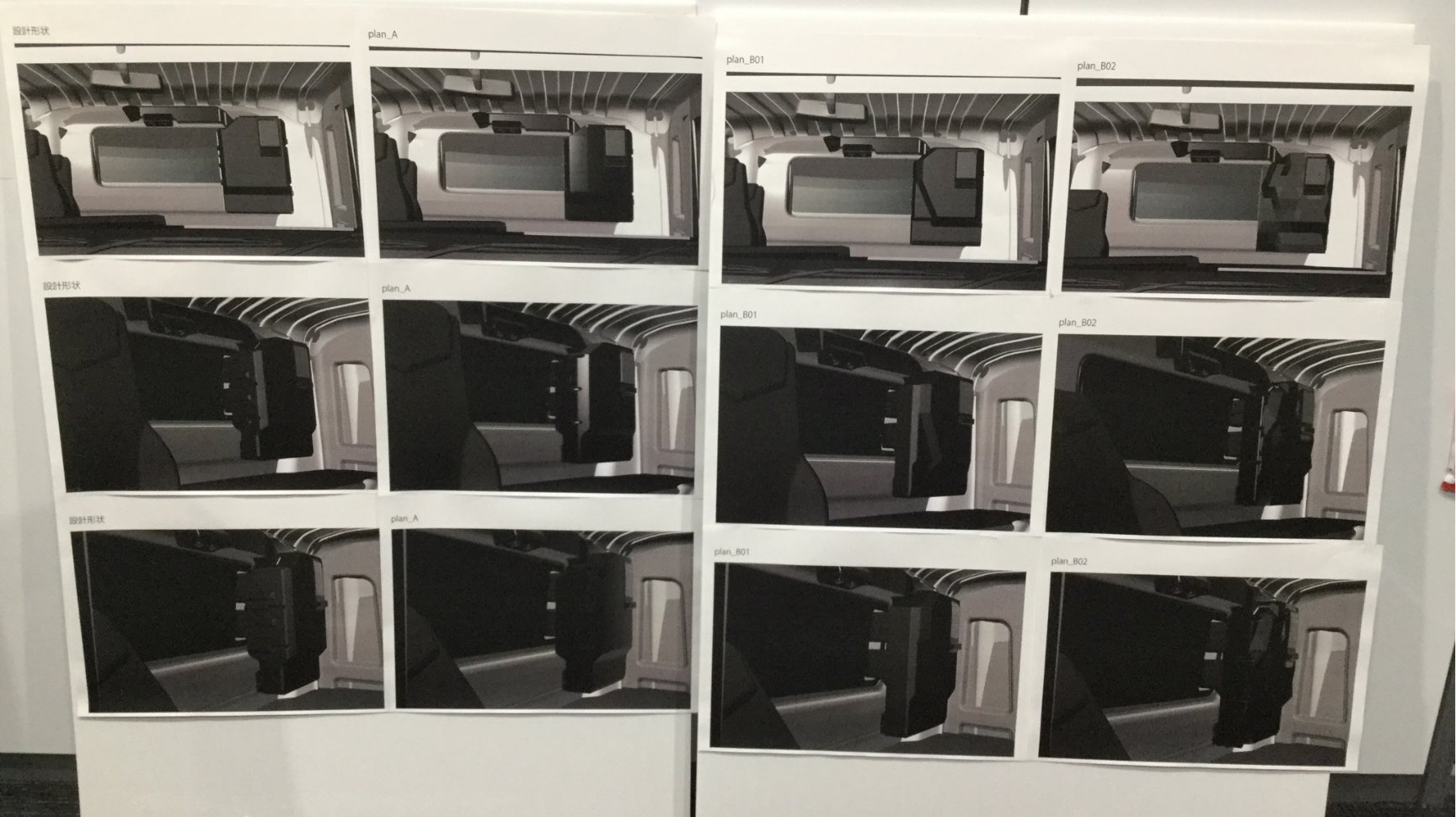

For making it appear smaller, we emphasized reducing the visual impact by tapering the corners and inclining the sides to create a sense of compactness. We primarily used CG and paper models for these considerations, building full-scale models from styrofoam and attaching them to walls for review. This process was relatively light and enjoyable.

Yoshida: I remember thinking Kasaiʼs paper models were incredibly well-made!

Oyama: Yes, the precision of those models was impressive, with angled cuts on the styrofoam surfaces, adding a level of accuracy.

Kasai: That was the most fun part for me.

Considering Time and Environment

Kasai: One memorable part of the design process was using 3D CG to create shapes that looked smaller. Oyama created several design proposals, and we reviewed them using VR goggles inside a virtual truck. We discovered that a design which seemed smallest in CAD actually appeared larger in the VR environment due to light direction and wall relationships. This highlighted the importance of situating the product in its intended environment to make accurate styling decisions.

Oyama: The benefit of using VR is the ability to change the environment, which is crucial for product evaluation. For example, this product needed to be evaluated inside a real truck and under different lighting conditions to see how it looks in various scenarios.

Kasai: Exactly. We tested how the product appeared in different lighting conditions within the VR environment, like at sunset or dawn. This reinforced the importance of considering the actual usage environment, time, and lighting.

Convincing with Prototypes

Yoshida: The controller for this product had to operate multiple functions with a single button, making the operation complex. The internal structure was fixed, so we couldnʼt change button positions. The main focus was on making the graphics clear and easy to understand. Adjusting the placement of icons and refining their meanings through detailed positioning was a valuable experience.

Oyama: Since trucks are used at night as well, visibility was crucial.

Yoshida: We considered which buttons to highlight and how to prioritize information. Users would gradually get used to the device, so we designed it to be intuitive, emphasizing the power buttonʼs position to guide users.

Oyama: We had to convince the technical department to reduce unnecessary text elements. They initially wanted to include all information, which, although detailed, made it confusing. Yoshida created an interactive prototype on a smartphone using XD to demonstrate our ideas effectively.

Yoshida: Yes, the interactive prototype helped communicate our design more effectively than words or documents alone, allowing us to move forward.

Oyama: Ultimately, the technical department supported our design, and we continued to refine details like LED colors within budget constraints.

Naming Process

Yoshida: We also worked on naming the product.

Oyama: We decided on "Everycool" through external surveys and using generative AI for brainstorming keywords. Surveys targeted long-distance truck drivers and logistics managers. Generative AI helped us explore keyword combinations, providing fresh ideas and perspectives.

From many candidates, we shortlisted names and conducted surveys internally and externally. The final name "Everycool" was chosen based on user feedback and collaboration with the technical department.

HX Perspective

Oyama: Kasai tested the product by lying on a real truck bed and using VR to simulate the truck interior, ensuring the design was user-centric. We also considered the perspective of logistics managers, proposing ideas like environmental awareness stickers and utilizing social media for promotion. Additionally, we had discussions with transportation journalists to understand industry viewpoints.

Kasai: Yes, we highlighted that the cooler, operating with the engine off, benefits the environment, drivers, and surrounding people by reducing noise and emissions. We aimed for a solution that makes everyone happy, including improving fuel efficiency for transportation companies.

Yoshida: The promotional video was also created with multiple perspectives in mind.

Oyama: The video needed to appeal to a broad audience, from those unfamiliar with idling-stop coolers to those already knowledgeable. It had to be versatile for various uses, such as Good Design Award applications, web promotion, and sales presentations.

Kasai: Through these efforts, we were delighted to win the Good Design Award. Thank you all for your hard work.

Tags

Member

Creative Direction: Toshifumi Mori

Project Management: Akira Okamoto

Project Lead: Kohji Ohyama, Hiroshi Kasai

Product Design: Kohji Ohyama, Hiroshi Kasai, Ayako Yoshida

Movie Design: Kohji Ohyama, Ayako Yoshida

UI Design: Kohji Ohyama, Ayako Yoshida

Other WorksAll Works

ActivitiesAll Activities